Products

Motors & Motion

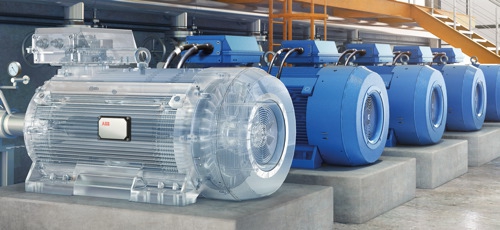

ABB motor sensing lets you know when it’s time for maintenance

August 3, 2016 | By Renée Francoeur

August 3, 2016 – A new sensing solution from ABB for 2016 can reduce downtimes of low-voltage motors by up to 70%, according to the company, and extend their lifetime by up to 30%.

Smart sensors attached directly to the motor provide information on operating and condition parameters such as vibration, temperature or overload and calculates power consumption via wireless transmission. The data is then analyzed by a specially developed software program and provided to the plant operator in the form of graphics for maintenance planning.

The sensors can be installed at the factory or retrofitted on already operating low-voltage motors, ABB notes.

The sensor is not electrically connected to the motor, so unauthorized parties cannot access the motor via this route. The smart sensors wirelessly transmit the data via encryption protocols to a server where they are analyzed using algorithms.

Print this page