News

GE scientists test cutting-edge traction motor for electric vehicles

July 26, 2012 | By Anthony Capkun

July 26, 2012 – Engineers at GE Global Research say they are advancing motor technology that could have a substantial impact on hybrid and electric vehicles (EVs) of the future.

“We have built a motor that is substantially more powerful than what’s commercially available now, all while improving efficiency by up to 5%,” boasted Ayman El-Refaie, electrical engineer, in GE Global Research’s Electrical Machines Lab.

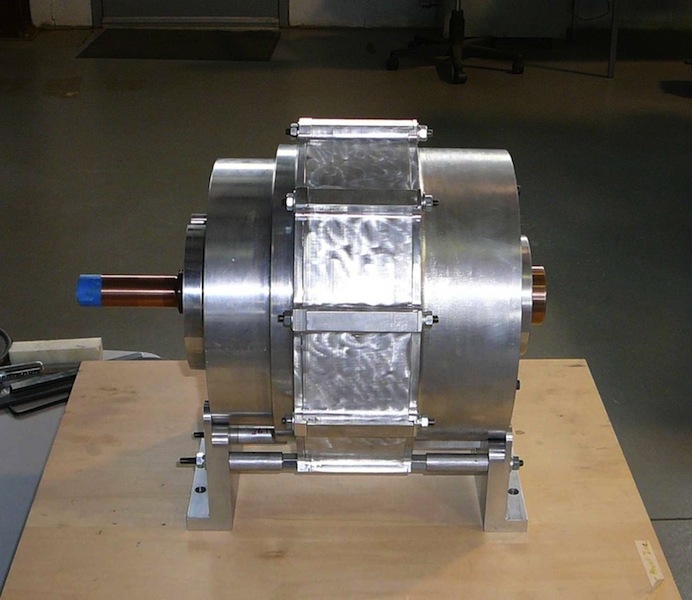

GE recently tested a prototype interior permanent magnet traction motor—developed as part of a $5.6-million U.S. Department of Energy (DoE) project—that could help extend the range EVs and hybrids can travel before recharging or needing gasoline. Engineers say the GE-designed motor less costly to make, and lab testing reveals it is more powerful and efficient than what’s on the market today. Combined, the additional power output and efficiency will help extend the range of EVs and delay the point at which hybrids switch to gasoline.

GE’s prototype traction motor operates at a peak power level of 55kW, and boasts nearly twice the power density (acceleration) of market-available traction motors (3% to 5% more efficient). Engineers say the required torque is achieved using much lower DC bus voltage (as low as 200V vs. 650V), and does not require a dedicated cooling loop.

“This technology is scalable and flexible enough that it can be leveraged in a number of capacities,” said El-Refaie. “What we learned through this project will help us build higher-efficiency industrial motors, high-speed oil & gas compressor motors, and generators for aerospace applications.”

Another important accomplishment of this project, says GE, was the development of high-resistivity permanent magnets, which reduces magnet losses and reduces or eliminates the need to segment the magnets.

Print this page