Features

Code File

Codes & Standards

High-voltage grounding requirements • Code File, April 2018

May 10, 2018 | By David Pilon

May 10, 2018 — Grounding around high voltage is very important; we ground not only for touch and step potentials, but to ensure equipotentiality within the installation.

Because we usually use the earth as the return on high voltage, it is not uncommon to have voltage gradients on the earth. This means more care needs to be exercised when installing the grounding around a high-voltage substation, and ensuring the earth in and around the substation are equipotential to the equipment and even the fencing.

Over the past few years, I have looked at a number of substations that have been missing a few important components that are covered in the CE Code, but are often installed incorrectly because rules are misinterpreted.

In the 2015 CE Code, the allowance for materials other than copper as a bare bonding conductor was introduced to help eliminate copper theft at a number of installations. This measure required effective interconnection between the equipment and the bare bonding conductor to ensure consideration was given to galvanic action. In the 2018 CE Code we do not see a number of significant changes; however we want to ensure that the installers are aware of the continued requirements for fencing, bonding and grounding around sub-stations.

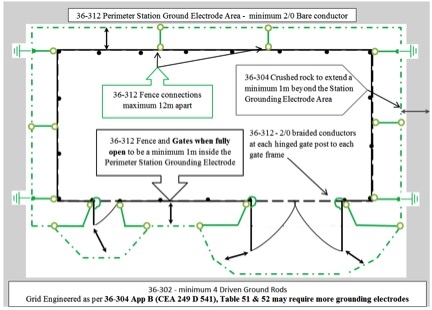

Let’s continue looking at the grounding and bonding requirements for the 2018 CE Code. The next minimum requirement is four (4) driven ground rods spaced at least one (1) rod-length apart and, where possible, adjacent to the equipment. Anyone involved in a substation will note that, on average, there are more than just four rods, and they are often spread out, as well as adjacent to the equipment.

However, these rods can be replaced with a buried station ground electrode with special permission, and can also be remote as necessary. Some factors that may come into play include the terrain on which they are located (e.g. Canadian Shield) and even the soil’s resistivity, which may require remote grounding. That is why engineering and ground studies are required—to look at the station ground resistance, soil resistivity and other factors vital to making these types of determinations.

Another area of concern is the installation of gradient mats, which are required around the gang-operated switch handles connected to the grid. The mats must be effectively connected to the grid to maintain a tolerable touch voltage during the operation of the handles. The mats must be located on 150mm of crushed stone and may also be covered a maximum of 150mm in depth. They must be placed so that the operator will not step o the mat while operating the handle trough’s revolution. By definition, each switch is a station; therefore, each must have the minimum of four (4) ground rods as per Rule 36-302.

The metallic fence enclosure around the station is another area of concern, as the design often overlooks issues with touch and step potential when opening gates. With the swing of the gates, it is important that operators not step outside of the grounding area. The gates are bonded to the fence using 2/0 flexible copper or flexible braid to keep them at the same potential as the rest of the fence, which is attached to the grounding electrode at 2-m intervals, corner posts and gate posts. That’s why, when the gates of a station swing outward, the station ground electrode area must remain 1-m outside of the fence, hence extending outward in these locations.

Lastly is the issue with the ground cover. Rule 36-304 states that where the safety of persons depends on the ground surface covering (such as crushed rock or asphalt), the covering layer shall extend throughout the grounding electrode area and 1-m beyond the station grounding electrode. That means the covering shall extend 2-m beyond the fence and, in the case of the gates with an outward swing, 2-m beyond their outer reach.

David Pilon is currently the Training Coordinator for Electrical Inspectors and has been an electrical inspector with SaskPower since 2000. He is also the vice-chair of the Canadian Certified Electrical Inspector (CCEI) committee of the International Association of Electrical Inspectors (IAEI), Canadian Section. David can be reached at dpilon@saskpower.com.

This article originally appeared in the April 2018 issue of Electrical Business Magazine.

Print this page