Features

Articles

LED lighting & driver issues • Ron Bergeron • April 2017

April 11, 2017 | By Ron Bergeron

April 10, 2017 – In the February 2017 edition of Electrical Business Magazine, I present real-life problems with LED lighting from the electrical contractor trenches, plus offer some research and best practices to help you make your installations successful.

LED lighting is a “switched mode power supply”, which means triplen harmonics, particularly the third harmonic. Not only is there a natural loading unbalance, but also the third harmonic adding up in the neutral conductor.

High-frequency energy is also being generated but, sadly, there isn’t much written about this. One research paper states: “A large number of LED lamps connected to a single feeder may introduce considerable harmonic current distortion and power quality problems”. That’s a game changer!

Let’s continue our exploration into LED lighting issues… including those that pan out as intended.

Situations from the front lines

1 Incandescent explosion-proof fixtures were commonly installed until about 20 years ago, but many are still operational. At each change of these short-lived bulbs, production must be halted and a skilled worker (usually on a stepladder) must take care when unscrewing the bottom section. It is heavy and must be set aside carefully, as it is expensive. Once the bulb is changed, the bottom is slowly screwed back, carefully so as not to strip the threads.

One electrician purchased a long-life LED bulb from a hardware store to replace the incandescent bulb. It works well.

2 A contractor installed four (4) LED pots in a residence. They were connected to a dimmer approved for them. Later, the client asked for four (4) more LED pots to be installed. Each fixture was rated 9W (36W for each set of 4). The dimmer was rated 150W so, even with four additional fixtures, the loading was well below capacity. The contractor connected the additional lights to the same dimmer.

Not long after, the contractor got a call from an irate customer, who complained of the lights flickering intermittently. After many costly hours of troubleshooting, the problem was identified, and a dimmer approved for eight (8) fixtures was installed.

3 The owner of a commercial establishment purchased dimmable LED lay-in panels (read “fixtures”), and a contractor was hired to replace the existing fluorescents. The following day, the owner’s staff removed the existing light switches and installed standard dimmer switches. When they did not function, the contractor was called back in. He informed the owner that, with 0-10V dimmers, a second set of wiring and matching dimmer was required. The owner had his existing light switches re-installed.

4 In a cafeteria, a contractor installed LED low-bay dimmable fixtures. The 347V power wiring and 0-10V dimming wiring were installed correctly. There were six (6) fixtures on one (1) circuit and one (1) nightlight fixture on a separate circuit fed from an emergency power panel. All seven fixtures operated from the same dimming circuit with a matching dimmer.

A few days later, one of the group of six fixtures failed. A replacement driver from the manufacturer was installed. When the circuit was re-energized, all 6 fixtures failed immediately. The nightlight was not affected. The cause of the failure is still unknown. The contractor had to replace all fixtures at his own expense. All functions well now.

5 A contractor installed an LED fixture (purchased by owner) with 3-way switching. When the switches are Off, there is a faint glow in the fixture. There were no issues with single-pole switching.

This same issue came up with another contractor in another location, only this time with single-pole switching. The glow went away when the bond wire was disconnected.

A homeowner bought LED bulbs to replace the incandescents in his closet fixtures. They are controlled by single-pole door switches. This worked well but for one closet where there was a faint glow. LED bulbs were switched from one closet to another, yet the glow remained in that one closet. The owner re-installed his incandescent bulbs.

Research

A It is not acceptable to use any type of replacement lamps in luminaires installed in hazardous locations, meaning any lamp that is not specifically tested and approved for use in a specific fixture (incl. incandescent, fluorescent, CFL, HID, induction and LED).

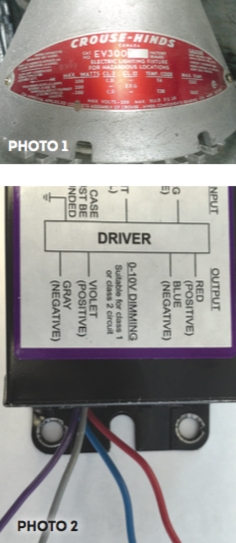

For example, Photo 1 shows the label from a Crouse Hinds incandescent fixture. It is very specific as to the lamp for this fixture. The use of anything other than the PS30 (or an A lamp) incandescent voids its certification.

Also, LED bulb electronics are considered an ignition source.

B Pot lights are popular and installer-friendly. The information is usually attached at the back of the box and, at first glance, the dimming information seems readily available. And everything looks straightforward on the spec sheet, too.

At times, the factory listing data is required to get all the relevant information. It is possible that a compatible LED dimmer rated 150W is only good for 36W (as per Situation #2, page 22).

C Dimming is complex.

1. Dimmer wiring for LED drivers is on the Output side (see Photo 2). Separate wiring is required with no power connections.

The 0-10V dimming is connected in parallel for all fixtures to be dimmed. This goes to a 0-10V dimmer that is installed separately from the light switch. Should the positive (Violet) and negative (Grey) become reversed—for even one fixture—or should the positive go to ground, the whole system dims to 10%. An open circuit results in no dimming. In semi-darkness, it’s easy to get the Blue and Violet confused.

2. There are other dimming variations, such as:

i. Pulse-width modulation

ii. Timing

3. Dimming can also be done by adding wireless modules mounted in the fixture. The question then becomes: “Is the fixture still CSA-approved as a unit?”.

D Some drivers are programmable and, at times, pre-programmed for a specific Output. The typical mode is constant current, but it can be constant voltage.

E As with all things, there are varying levels of quality across LED light sources and drivers. Higher-end solutions have over voltage protection (OVP), short-circuit protection (SCP) and over-temperature protection (OTP). A solution providing all three may be referred to as All-Around Protection. Lower-end solutions have none of these protections.

F You only need a few microamps for an LED to give off visible light. Glowing can occur when the neutral is switched instead of the line.

Best practices

1 In hazardous locations, do not use any retrofit kits or lamps. (In my opinion, the inspection authority—ESA in Ontario—should issue a directive about this.)

2 Look closely at compatibility charts every time you install LED lights, especially when dimming using traditional wiring. The usual method of dimmer selection is no longer sufficient.

3 Do not make assumptions about 0-10V dimming. Do not add components to fixtures unless compatible, as per the manufacturer’s instructions, and approved by CSA.

4 Solutions are increasingly complex, and you’ll come across both good and bad product. Train your staff to look closely at all the information and to ask questions. Mistakes are costly.

5 Do not disconnect bonding wires. This creates a hazard and is a Code violation.

6 Ensure switching cuts the line. LEDs light up the code violation of cutting the neutral.

Some other best practices:

• Examine the LED driver to ensure it is approved for use in Canada. Verify the rating for voltage, and whether it is phase-to-neutral or phase-to-phase.

• Disconnect both phase and neutral when shutting off parts of a multi-phase system.

• Use high-inrush contactors.

• Ensure all components are from the same manufacturer or declared compatible by the manufacturer.

• Bond with a separate insulated wire the same size as the phase wiring.

These recommendations are based on either what I’ve seen myself or learned from other electrical contractors, and I am certain other issues will come to light. Please let me know of the problems you’ve encountered, and whether you’ve stumbled upon any solutions.

A regular contributor to Electrical Business Magazine, Ron Bergeron is a master electrician, professional engineer since 1969 and an electrical contractor since 1971. He was also involved with Ontario’s Electrical Safety Authority as a member of the Industry Advisory Council, Fee Restructuring Committee and Contractor Advisory Council. He is currently on the Board of the Ontario Electrical League and a Council member of the Electrical Contractor Registration Agency for Ontario. He can be reached at ronb@bergeronelectric.com. Also check out his article “Time for an LED lighting reality-check” EBMag February 2017, p. 12.

* This article also appears in the April 2017 edition of Electrical Business Magazine. Check out our ARCHIVE page for back issues.

Print this page