News

Understanding Industrial Ethernet standards by Ron Groulx Feb09

February 27, 2009 | By Anthony Capkun

Understanding Industrial Ethernet standards

By Ron Groulx

When working in the design and installation of an industrial network, technicians often find themselves facing a bewildering array of standards written by numerous international, regional, national and trade organizations. The foundation for ensuring successful plan, installation and maintenance of an Ethernet network is an understanding of the key standards in use today and their applications.

Ethernet

standards used in industrial environments are more complex and

stringent than those in office environments. That is because the

mission-critical control-based applications traffic carried on an

industrial network demands extremely high reliability with

deterministic timing. In production environments there is far less

tolerance for any excess latency that can lead to slowdowns or even

breakdowns. Besides the standard throughput and performance issues,

there are specific standards also address the extra stresses of harsh

environments such as vibration, electrical noise, equipment in motion,

impact dangers, and all manner of contaminants. Finally, standards play

an important role in ensuring application backward-compatibility with

legacy systems—a key factor in any industrial implementation.

Cutting through the confusion

Given

Given

the myriad of factors to consider, getting a handle on industrial

Ethernet standards can be extremely confusing and challenging. For

example, the standards that apply to designing cabling components or

networks for commercial and industrial Ethernet include ISO/IEC 11801,

the ANSI/TIA 568 series, ISO/IEC 24702, IEC 61158-1, – 2, IEC 61784-1,

-2, and ANSI/TIA 1005 apply. When planning and installation of the

physical infrastructure for industrial Ethernet automation networks,

technicians need to apply ISO/IEC 14763-2, IEC 61918, and 61784-5

standards to ensure robustness, compatibly, and maintainability.

While

this all seems overwhelming, proper education and training can help

sort through the confusion. A good place to start is gaining an

understanding of the various technical committees, their areas of focus

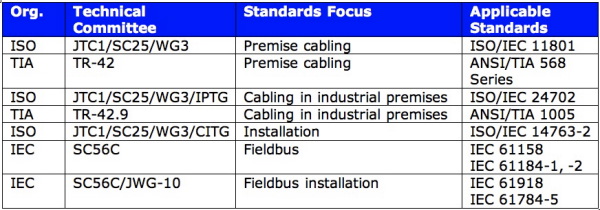

and their standards. Table 1 provides a basic outline of those

committees and their areas of focus.

In

addition to ISO, IEC and TIA, there are other regional cabling

standards groups—including CSA (Canadian Standards

Association)—that develop specifications for their geographic area or

country. These regional standards are usually in harmony with ISO, IEC,

and TIA requirements.

{mospagebreak}

The standards explained

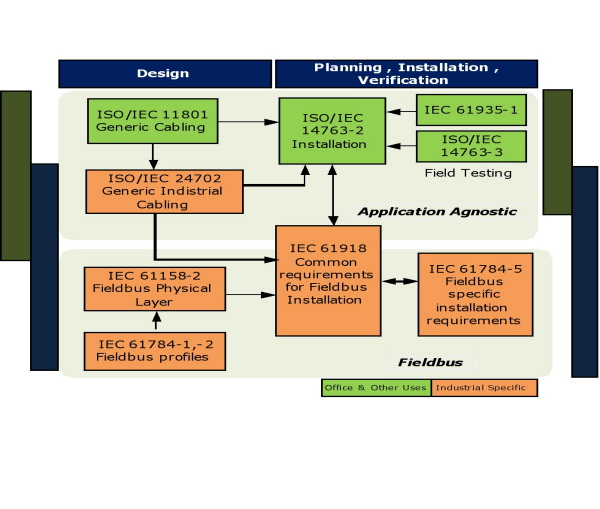

Figure 1

outlines the specific standards that a technician should know when

working with industrial Ethernet. It maps out the key ISO, IEC and

joint ISO/IEC standards required in the design, and then in the

planning, installation, verification, and testing of industrial

Ethernet.

Looking at the “application agnostic” portion of the chart, following is a brief explanation of the standards:

•

ISO/IEC 11801 is the base standard covering generic structured cabling.

It covers cabling systems that are typically used for premise local

area networks and specifies end-to-end physical media and transmission

performance.

•

•

ISO/IEC 14763-2 specifies planning, installation, and operation of

infrastructures in support of generic cabling, including implementation

of cabling, pathways, spaces, grounding and bonding. It covers work

specifications, quality assurance, installation planning and practice,

documentation and administration, testing, inspection, operation and

repair and maintenance.

• IEC

61935-1 and ASO/IEC 17463-3 specifications cover field testing based on

the ISO/IEC 11801 standard for copper and fiber respectively.

•

ISO/IEC 24702 builds upon the office premise generic cabling standard

ISO/IEC 11801, and modifies the requirements for industrial premises,

taking into account MICE (mechanical, Ingress, climatic and

electromagnetic) classifications.

{mospagebreak}

The “Fieldbus” portion of the chart addresses the following standards:

• IEC

61158-2 specifies ‘Fieldbus for use in industrial control systems –

Part 2: Physical Layer specification” that covers non-Ethernet Fieldbus

cabling. This document should be used in conjunction with the Fieldbus

profiles documents IEC 61784-1 and IEC 61784-2 to specify the cabling

requirements for individual non-Ethernet Fieldbus implementation.

• IEC

61918 standardizes common elements across all the Fieldbuses, and IEC

61784-5 provides profile-specific installations requirements. Use these

two documents as a set to specify installation requirements.

Specification

documents for these products are large and can be rather expensive. The

IEC does however package and sell groups of IEC 61158, IEC 61918, and

61784 documents pertinent to the Fieldbus being used.

How the TIA specifications fit in

One other factor to consider is the TIA generic cabling standard series.

ANSI/TIA-568

is fairly well aligned with the ISO/IEC generic cabling standard 11801

with some terminology differences. A few examples are:

• An ISO equivalent of a TIA category 5e installed cable system is ISO Class D.

• An ISO equivalent to a TIA category 6 installed cable system is Class E.

•

ISO/IEC 11801 references a separate IEC specification that covers

component performance such as individual connectors. These IEC

component specifications use the same category 5e/6/6A performance

classifications as TIA.

•

TIA-1005 “Telecommunications Infrastructure Standards for Industrial

Premises” is the TIA equivalent of ISO/IEC 24702. This standard adds

topology, environmental and electrical transmission requirements for

industrial premises.

Getting help

Anyone

unfamiliar with these standards can contact the appropriate trade

organizations for additional information. Fieldbus developers for

example offer an excellent source of standards-compliant application

guides for their products. Additional information and support can also

be found through organizations such as BICSI, IEAG and ISA.

This is

only a basic sampling of what technicians need to know when working

with industrial Ethernet standards. Getting the proper education and

training are integral to ensuring the success of any Ethernet design,

installation and maintenance process. While it does take time, effort

and training, getting to know the ropes is definitely worth the

investment over the long term.

Ron

Groulx is product manager for FLUKE NETWORKS CANADA. Having worked in

the industry for almost ten years and a graduate in computer science,

he is knowledgeable in all aspects of networking from cabling

infrastructure to network monitoring and troubleshooting. E-mail

ron.groulx@fluke.com to contact the author.

Print this page