Articles

Features

Articles

Test & Measurement

What do CAT ratings mean?

April 7, 2023 | By Teledyne-FLIR

Comprehending safety ratings for electrical tools, test & measurement equipment

Source: © ELENABSL/ADOBE STOCK/STAFF

Source: © ELENABSL/ADOBE STOCK/STAFF April 7, 2023 – The International Electrotechnical Commission develops and distributes international standards for electrical technologies, including for devices used to identify, test and measure live electrical circuits.

Known as the “measurement category”, this method of classification examines the total potential continuous energy available at any point within a circuit, including the potential for transient voltages that can spike voltages well beyond normal levels.

Transient voltages can be caused by lightning strikes, arcing, or other naturally occurring electrical phenomena, which can pose significant danger to personnel working on or around electrical equipment—from fixing a copy machine through to examining power utility infrastructure.

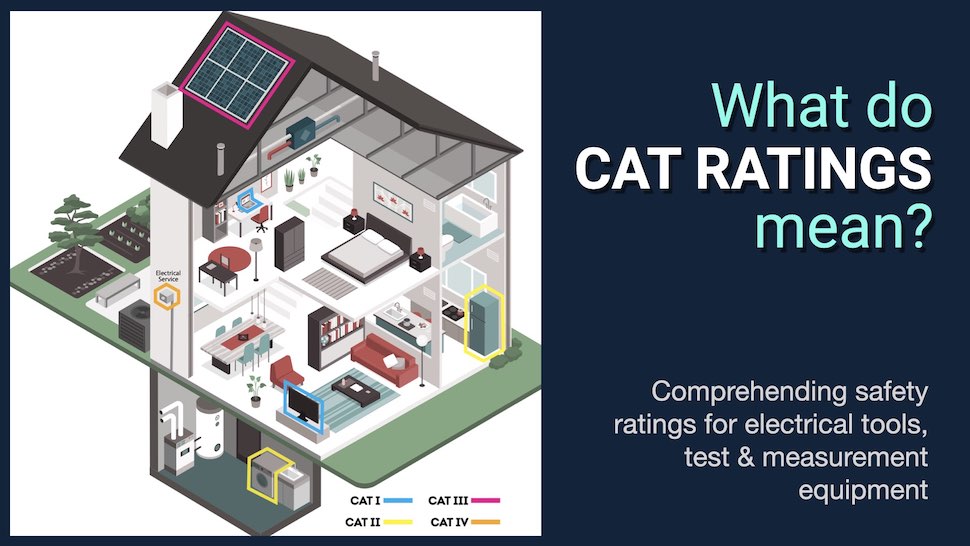

Measurement categories are divided into four parts, known individually as category (CAT) ratings: CAT I, CAT II, CAT III, and CAT IV. Understanding what each of these categories means is vital for choosing the right equipment for the job to avoid exposure to unnecessary risk.

In short, the rating system will inform anyone working with electrical equipment about the right tool for a job; whether a basic multimeter will suffice through to selecting the right devices for industrial utility infrastructure inspection.

Understanding voltage ratings

In the CAT rating system, the Roman numerals I through IV refer to the location of a circuit in relation to the power source, defined in terms of the total potential transient voltage danger.

CAT I describes secondary circuits not intended to be connected to the mains electricity supply, such as electronics (including a typical laptop) and circuits powered by regulated low-voltage sources.

CAT II is defined as local-level electrical distribution, such as a standard mains socket and plug-in loads. This category includes household appliances, such as washing machines, and portable plug-in power tools.

CAT III references a building’s electrical installations, including circuit breakers, wiring, switches and industrial equipment.

CAT IV involves the source of the low-voltage power installation; essentially, the power grid infrastructure, such as underground utility vaults or outdoor powerlines.

However, determining the appropriate voltage category is only half the story. Simply matching the presumed voltage to the test & measurement device will not provide adequate safety assurance. Failed electrical units can experience impulse or transient voltages on the order of many times a particular electrical tool’s rating.

For example, a line may normally have a voltage of 120 or 240, but a lightning strike can create transient voltage—perhaps several thousand volts—that can cause a short-circuit and arcing, which could severely injure personnel testing the power infrastructure with inadequate equipment.

In essence, then, not only must the tool have the appropriate CAT rating for the application, the device must also have a voltage rating higher than the maximum voltage of the given environment to withstand potentially dangerous surges in voltage.

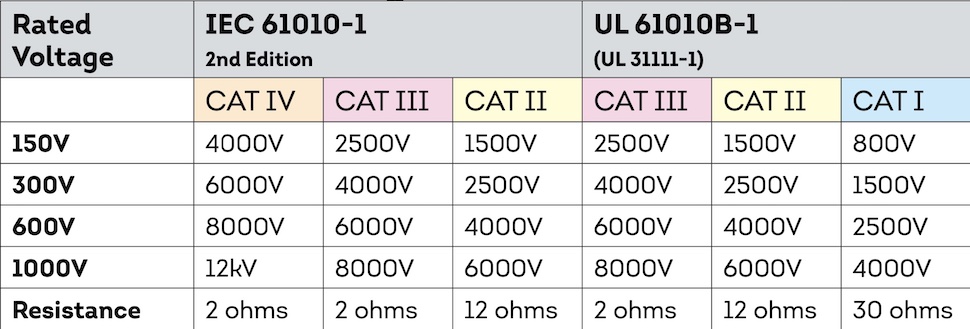

Thankfully, IEC supplies a quick-reference chart to determine whether a given electrical tool is appropriate for the task at hand.

Matching the right electrical tools for the job

If a given specification requires a tool to be rated for CAT III 600V and CAT II 1000V, then the module can withstand up to 6000V of impulse or transient voltage. This type of spec would additionally inform the user that the device must not be used with mains CAT III circuits with the potential for voltage to rise above 6000V.

Conversely, the tool or device rated in this manner should not be used with CAT IV circuits under any circumstances, even when a particular scenario does not require more than 6000V.

Ultimately, the purpose of the CAT rating system is to provide a quick and easy-to-understand method for selecting the right tool for the job; to know if a given tool is designed for a particular application/scenario or not. A quick check adds an additional level of safety, helping to prevent serious injury—or even death—that could result from severe shock, fires or explosions.

— Contributed by Teledyne-FLIR

You’ll find all Back Issues of Electrical Business Magazine in our Digital Archive.

Print this page