Articles

Features

Uncategorized

Articles

Risks and mitigation strategies for absence of voltage testing

October 20, 2020 | By Bhanu Srilla

Risks and mitigation strategies for absence of voltage testing, EBMag October 2020.

Risks and mitigation strategies for absence of voltage testing, EBMag October 2020. October 26, 2020 – Absence of voltage testing is the most vital step in the process of verifying and establishing a deenergized state of any electrical system. According to Clause 4.2.5, CSA Z462 (2018), it is a process-oriented approach that takes various steps to establish a deenergized state and is not accomplished with any single device. Verifying a deenergized state is further a risky task which requires strict adherence to policies and procedures to establish a safe environment to work.

Because it is a high-risk task, verifying a deenergized state requires strict adherence to policies and procedures.

Additionally, it is also a regulatory requirement per OHS guideline Part 19 (WorkSafeBC), OHS Code 2018, Alberta, Rule 4-086, and Subsection 215.1(3)(d). Historical data suggests high incident rates of both shock and electrocution because of performing the task of “absence of voltage testing” inside electrical cabinets. The data further points out that the incidents are primarily caused due to workers’ inadvertent contact with electrical circuit parts inside the panel, wrong application of test instruments, human error, production pressures, and complacency.

Many safety-centric organizations and product innovators have devised a variety of methods to minimize the risk of exposure to workers from the hazards of presence and absence of voltage testing over the past several decades.

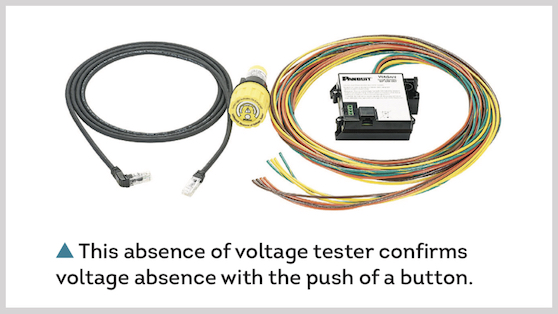

In CSA Z462’s 2018 edition, a Supplemental Method in Notes No. 1 allows an alternative method through a new exception for the same task under clause 4.2.5(g). This document delineates the differences between presence and absence of voltage testing from the application standpoint of lockout/tagout and compares the pros and cons of these devices, and their limitations of use.

Products discussed include, voltage indicators, test portals, permanently mounted accessories, portable test instruments, and absence of voltage testers. Given the process-centric approach, additional clarification is placed on worker qualification, installation conditions, training requirements, procedures, and failure modes of these risk control methods and their effect on both the task and the worker.

Risks and mitigation strategies for absence of voltage testing, EBMag October 2020.

What are test portals?

Conductive versus non-conductive

Test portals are permanently mounted accessories and are classified into two categories based on the application of use:

• Portals that are non-conductive and use non-contact voltage detector pen (NCVD) for voltage detection.

• Portals with conductive test points that use portable test instruments and test probes for absence voltage testing and troubleshooting.

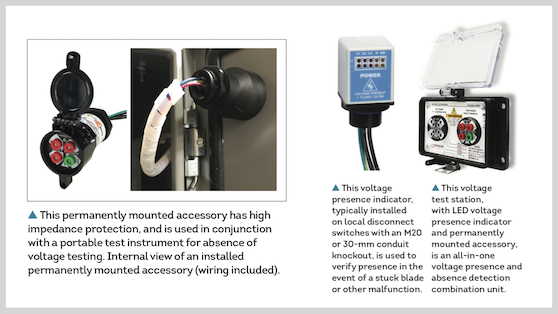

Permanently mounted accessories that are cUL 61010 listed devices are meant for voltage testing using an adequately rated portable test instrument. The cUL classification further terms this product as “panel-mounted test point meter”. These devices can be used for both troubleshooting the equipment, and to verify the absence of voltage from the source to which they are connected.

Risks and mitigation strategies for absence of voltage testing, EBMag October 2020.

Why use test portals with test points?

Test portals with test points greatly reduce the risk of exposure to qualified electrical workers, as they use built-in high impedance protected circuitry. Further, when it comes to electrical safety, there is no such thing as absolute zero risk failure modes associated with any type of risk control method.

Hence, there is no shock or arc flash hazard for the worker performing the task. Compared to the conventional method of absence of voltage testing inside an electrical cabinet—assuming the system is still energized—these devices provide a much safer alternative to verify the absence of voltage as outlined in the both clause 4.2.5(g), CSA Z462 (2018) and OHS Guideline Part 19 (WorkSafeBC), OHS Code 2018, Alberta, Rule 4-086, and Subsection 215.1(3)(d).

CSA Z462 shows six risk control methods that are required to be implemented per Annex F.3, Table F.1. The hierarchy of risk control methods (RCH) classifies risk controls across six categories:

• Elimination

• Substitution

• Engineering controls

• Awareness

• Administrative controls

• Personal protective equipment

They range from more effective (at the top) to less effective (at the bottom).

The purpose behind the RCH chart is to identify and apply a single or combination of risk control methods that are suitable for the specific application and the task being performed.

Permanently mounted electrical safety devices fall under the engineering controls category.

cUL 61010 Listed permanently mounted devices

Permanently mounted devices that are listed and labeled to cUL 61010 are not allowed to have plug ends. These devices are not meant to be connected using a corded supply; they are only intended for permanent connection.

Poor workmanship, installation failures and device malfunctions are all potential failure modes that can lead to a zero-voltage indication/no indication when the conductor may still be energized.

Typical absence of voltage tester (AVT) potential failure modes:

1. Missing battery or wrong battery in the indicator module.

2. Accidental disconnection of leads and contacting low-impedance ground path leads to false indication of absence.

3. Loose/disconnection of AVT system cable connecting from the isolation module to the door module.

4. Miswiring of leads by connecting one set to the line side and second set to the load side on the connections.

5. Wrong application of device in Cat IV, 600V environments when the device is only rated for Cat IV, 300V.

6. Misinterpretation of the fault codes by the operator.

All of which make a stronger case for permanently mounted devices.

Risks and mitigation strategies for absence of voltage testing, EBMag October 2020.

Know your clauses

When you cannot verify the absence of voltage from outside the door, then verify a deenergized state inside the panel with an adequately rated portable test instrument.

Per CSA Z462 (2018), Clause 4.1.9.1, only qualified persons shall perform the absence of voltage testing. The qualified person is the one who knows what steps must be taken when the absence of voltage cannot be verified from outside an electrical cabinet.

Clause 4.1.9.5 “Operation verification” explains that when test instruments are used to verify the absence voltage on conductors or circuit parts operating at greater than 30 V, the operation of the test instrument itself shall be verified to a known voltage source before and after an absence of voltage test is performed.

Z462 Clause 5.2.1 “Qualified persons” specifies only qualified persons shall perform tasks such as testing, troubleshooting and voltage measurements on electrical equipment operating at voltages greater than 30 V. This clause also specifies the rating of instruments, equipment and their accessories:

• Rated for circuits and equipment where they are utilized

• Approved for the purpose

• Used in accordance with the instructions provided by manufacturer

The informational note further clarifies the use of cUL 61010-1 listed products for the equipment used in systems 1000 V and below.

Sorting out the puzzle

CSA Z462 provides broad language that allows users to customize their safety programs to meet their precise needs. As such, many manufacturers have devised methods and new types of devices to reduce worker risk that are not even mentioned in Z462 (e.g. a dual-interlocked disconnect switch).

Safety is a condition in which one is being protected from the risk of injury or hazard and is not something that can be attained by just installing a device at the door.

It is simply one more piece of the electrical safety puzzle that helps ensure our qualified workers can execute their daily tasks and go home, uninjured, at the end of the day.

With over two decades of experience in the power generation and distribution industry, Bhanu Srilla, MS, CESCP, CMRP, CRL, is director of technical marketing with Grace Technologies. He is an IEEE member, and a member of Standards Technical Panel STP for UL 1436, UL 61010, UL 508 and 508A. He is a certified electrical safety compliance professional (CESCP) by NFPA, certified maintenance and reliability professional (CMRP) by SMRP, certified reliability leader (CRL) by Reliability Web, and holds advanced degrees in Electrical Engineering, Manufacturing Systems, and Technology Management.

This article—along with other great content—appears in the October 2020 edition of Electrical Business Magazine.

Print this page