Features

Energy & Power

Generation

MIT tackles ‘boiling crisis’ to improve power plant output and safety

September 8, 2015 | By Anthony Capkun

September 8, 2015 – From the operation of electric power plants to chemical processing and desalination, the boiling of water is at the heart of many industrial processes, but the details of what happens on a hot surface as water boils have been poorly understood, say researchers at MIT, so unexpected hotspots can sometimes melt expensive equipment and disable plants.

Those researchers say they have developed an understanding of what causes this extreme heating—which occurs when a value known as the critical heat flux (CHF) is exceeded—and how to prevent it, adding these new insights could make it possible to operate power plants at higher temperatures and, by extension, higher overall efficiency.

The findings are reported in Nature Communications in a paper co-authored by mechanical engineering post-doc Navdeep Singh Dhillon, professor of nuclear science and engineering Jacopo Buongiorno, and associate professor of mechanical engineering Kripa Varanasi.

“Roughly 85% of the worldwide installed base of electricity relies on steam power generators and, in the U.S., it’s 90%,” Varanasi says. “If you’re able to improve the boiling process that produces this steam, you can improve the overall power plant efficiency.”

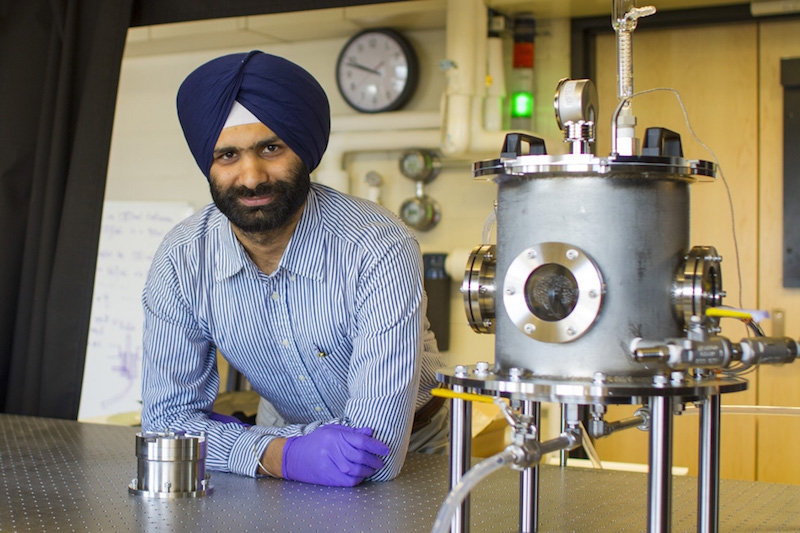

PHOTO: Post-doc Navdeep Singh Dhillon studies the fundamental physical mechanisms that dictate the boiling crisis phenomenon. At right is a rig for measuring the critical heat flux (CHF) of thermally saturated water boiling on thin textured substrates, which allows researchers to visualize bubbles and measure real-time spatial substrate temperatures using infrared imaging. Photo Jose-Luis Olivares, MIT.

As it turns out, the bubbles of vapour that characterize boiling limit energy efficiency. That’s because gas—whether it’s air or water vapour—is highly insulating, whereas water is a good absorber of heat. So on a hot surface, the more area that is covered with bubbles, the less efficient the transfer of heat energy becomes.

When those bubbles persist too long at a given spot, it can significantly increase the temperature of the metal underneath, since heat is not transferred away fast enough, Varanasi explains, and can potentially melt part of the metal.

“This will most certainly damage an industrial boiler, a potentially catastrophic scenario for a nuclear power plant or a chemical processing unit,” says Dhillon. When a layer of bubbles limits heat transfer, “locally, the temperature can increase by several thousand degrees”—a phenomenon known as a ‘boiling crisis’.

To avoid exceeding the CHF, power plants are usually operated at temperatures lower than they otherwise could, limiting their efficiency and power output. Using textured surfaces has been known to help, but it has not been known why nor what the optimal texturing might be.

The researchers’ work shows that more texturing is not always better. The MIT team’s experiments, which use simultaneous high-speed optical and infrared imaging of the boiling process, show a maximum benefit at a certain level of surface texturing; understanding exactly where this maximum value lies and the physics behind it are key to improving boiler systems.

“What was really missing was an understanding of the specific mechanism that textured surfaces would provide,” Buongiorno says. The new research points to the importance of a balance between capillary forces and viscous forces in the liquid.

“As the bubble begins to depart the surface, the surrounding liquid needs to rewet the surface before the temperature of the hot dry spot underneath the bubble exceeds a critical value,” Varanasi says. This requires understanding the coupling between liquid flow in the surface textures and its thermal interaction with the underlying surface.

“If anything can enhance the heat transfer, that could improve the operating margin of a power plant,” Varanasi says, allowing it to operate safely at higher temperatures.

By improving the overall efficiency of a plant, it’s possible to reduce its emissions: “You can get the same amount of steam production from a smaller amount of fuel,” Dhillon says. At the same time, the plant’s safety is improved by reducing the risk of overheating, and catastrophic boiler failures.

Print this page