Articles

Features

Articles

Best practices for electric motor storage—Protecting your investment

December 7, 2020 | By Chuck Yung

What is not always apparent is that some smaller motors are equally important to production, and can have enormous consequences if they fail.

Photo @ Mulderphoto / Adobe Stock

Photo @ Mulderphoto / Adobe Stock December 7, 2020 – Storing an electric motor for more than a few weeks involves several steps to ensure it will operate properly when needed. For practical reasons, these are governed by the motor’s size and how long it will be out of service. Factors like temperature, humidity and ambient vibration in the storage area also influence the choice of storage methods, some of which may be impractical for smaller machines or need to be reversed before the motor goes into service.

With these things in mind, here are some common recommendations for storing motors.

Keep good records

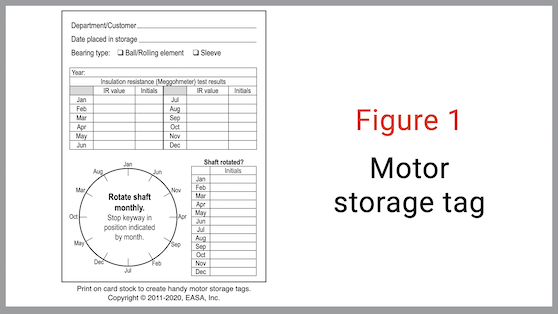

Good, readily-available records are essential for any motor storage program. One method is to attach a card like that in Figure 1 to each motor to document the storage dates, maintenance procedures completed, and the results of all tests performed during the storage period.

For motors in long-term storage, a good practice is to replace that card annually (or other designated intervals), and to store electronic copies of the previous forms for future reference (or simply keep them in an envelope attached to the motor).

Storage conditions

Short-term storage

Motors that will be in storage for just a few weeks primarily require protection from the weather and ambient vibration (more on this below).

Long-term storage

Motors slated for several weeks to several years in storage (as well as all above-NEMA-sized machines) require additional preparations to protect their machined surfaces, bearings and windings.

Indoor storage

When possible, store motors indoors in a clean, dry area. Place horizontal machines in a horizontal position and vertical motors in a stable vertical position.

Unless the storage area is climate-controlled, prevent condensation from forming inside the motor by energizing the space heaters (when supplied) to keep the windings 5-10 C above the ambient temperature. (More ways to prevent condensation discussed below.)

Outdoor storage

Don’t do it! Seriously, when a motor is too large to store indoors, then it is likely to be a very expensive machine. Trust me, it is worth the cost to construct an enclosed storage facility.

But when outdoor storage is absolutely necessary, protect the motor with a water-proof cover (e.g. a tarp), allowing breathing space at the bottom. Do not wrap it tightly in plastic as temperature extremes and humidity will cause condensation to form inside the motor.

Outdoor storage also requires preventive measures to keep out rodents, snakes, birds, etc., that can damage the winding insulation. When insects are prevalent, keep them from blocking ventilation and drain openings by loosely wrapping the motor and covering all openings.

Shafts and machined surfaces

Apply a viscous rust/corrosion inhibitor (e.g. LPS2, Techtyl 502C or RustVeto) to exposed machined surfaces and sleeve bearings, which allows it to remain intact throughout the storage period. In humid and rainy/snowy environments, have the service centre paint as much of the motor’s interior surface as practical. For tropical environments (I know, this is Canada we’re talking about), coat the windings with a topical fungicide. (Note: Disassemble the machine and inspect the sleeve bearings before placing it into service.)

Bearing protection

Grease-lubricated motors

For long-term storage, completely fill the bearing cavities with compatible grease to prevent rust and corrosion staining that can occur should moisture collect between the balls and races.

Oil-lubricated motors

Do not ship or move these motors with oil in the reservoir. After placing the motor in storage, fill the reservoir with enough oil to cover the bearings but without over-flowing the stand tube or labyrinth seal. Fill sleeve-bearing machines to just below the labyrinth seal and vertical motors to the Max Fill line.

The oil should contain a rust and corrosion inhibitor, and be moisture-free. Check it every three months by drawing a sample from the drain. Since water weighs more than oil, any moisture will be evident.

TIP: Never move a motor with oil in the reservoir. Oil that sloshes over the stand tube could contaminate the windings or even initiate capillary action that can siphon oil from the chamber. Before putting the motor into service, always drain the oil and replace it with compatible lubricant. Drain it. Move it. Refill it.

Ambient vibration

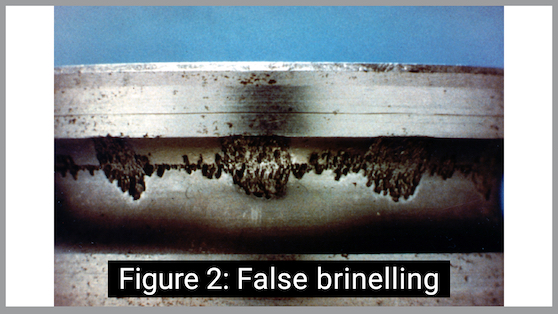

This can damage motors, even when they are not rotating. Proximity to rail lines, busy roads and/or production floors can all contribute to the ambient vibration. Even low-magnitude vibration, over time, can damage bearings while they are stationary (Figure 2). Solutions vary; one mill with ambient vibration from nearby machinery stored its motors on scrapped conveyor belting.

False brinelling damages the bearing race at uniform intervals matching the spacing of the rolling elements. Although the damage initially may appear slight or even invisible to the naked eye, it often progresses rapidly once the motor is in service.

(Brinelling is named after the Brinell scale of hardness, in which a small ball is pushed against a hard surface at a preset level of force. The depth and diameter of the mark that is left indicates the brinell hardness of the surface. False brinelling is caused by vibrations acting on the bearing while in a non-rotating state.)

Shaft rotation

Turning the motor’s shaft at least monthly during long-term storage redistributes lubricant on machined surfaces to inhibit corrosion. Motors with ball or roller bearings also benefit from monthly rotation, since the rolling elements stop in different positions each time. Larger, 2-pole machines require more frequent attention than smaller (NEMA-frame) machines.

Motors with spring-loaded spherical bearings are more difficult to turn, but they still require manual rotation to coat the bearings with oil. With sliding plate (i.e. Kingsbury) bearings, lift the shaft before rotating it (from below with a short jack and a bearing ball centred on the shaft) or from above with an overhead crane and eye-bolts. To avoid bearing damage, be careful not to lift the shaft more than a few mils.

Machines with heavy rotors and long frames in ratings of about 2000 hp (1500 kW) and larger sometimes require more frequent (weekly) rotation to prevent shaft bow-ing caused by the weight of the rotor. Power plants, for example, often keep large turbine generators rotating slowly all the time to prevent sag. While it is uncommon, removing and vertically suspending the rotors of very large critical machines also can prevent sagging.

TIP: Rotating the shaft keyway position in 150-deg increments every month makes it easy to spot a neglected motor. If you visualize a clock face, each increment represents 5 “hours”. For example, if the keyway position for September is 12:00, October will be 5:00, November will be 10:00, and so on. This puts the rolling elements in a different position each time and avoids rocking the rotor back and forth between just two positions (Figure 1).

Special care for motor windings

Methods for preventing condensation

Motor windings must stay clean and dry to keep the insulation from degrading. Un-less the storage area is climate-controlled, condensation can form in the motor when the temperature of the winding dips below the dew point. As mentioned earlier, the usual way of avoiding this is to keep the winding 5-10 C above ambient.

When the motor has space heaters, energize them while in storage; if not, add them. Another option is to use the windings as a resistance heater by supplying low-voltage DC current (about 8-12% of rated amperage). An energy-saving alternative is to lower the dewpoint of the storage room with a dehumidifier.

Insulation resistance (IR) tests

Measure and record the IR of the winding(s) before storing a motor, even if just for a few weeks, then again before putting it into service (Figure 3). Correct all IR readings to a standard temperature and address any decrease in IR before installing the motor. When a motor will be in storage for a long time, take IR readings annually.

Polarization index (PI) and dielectric absorption (DA) ratio tests

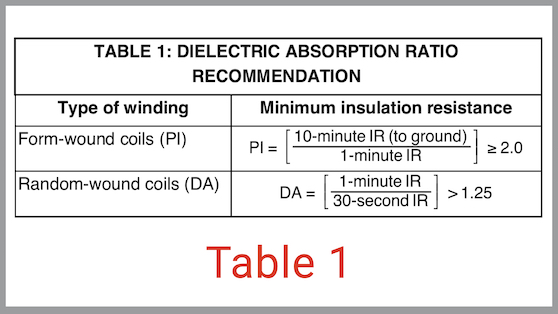

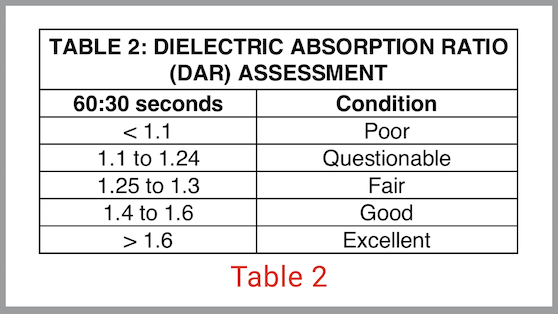

For form-coil windings, conduct a PI test in addition to the IR test. The PI test variables skew results for windings with lots of exposed conductor surface area, so use the DA ratio test for random windings and DC armatures (Tables 1 and 2).

If the windings need to be cleaned and dried, measure the IR again. When it is greater than 5000 megohms, disregard the PI (see IEEE 43); otherwise, recalculate the PI.

TIP: Attach a card to each motor and record the IR, temperature and date of each test.

Carbon brushes

DC machines, wound-rotor motors and some synchronous machines have carbon brushes. For long-term storage, lift the brushes away from the commutator/slip rings to prevent a chemical reaction (sometimes called “photographing”) that can discolour the underlying commutator or slip ring. When practical, store the springs in the relaxed state to prevent a gradual loss of spring pressure.

Follow best practices… even for “small” motors

High-cost machines obviously justify more precautions than inexpensive, readily available motors. That said, what is not always apparent is that some smaller motors are equally important to production, and can have enormous consequences if they fail.

Chuck Yung is a senior technical support specialist at the Electrical Apparatus Service Association (EASA), an international association of more than 1800 firms in about 70 countries that sell and service electromechanical apparatus. Visit www.easa.com.

This article—along with other great content—appears in the December 2020 edition of Electrical Business Magazine.

Print this page