Articles

Features

Articles

Energy & Power

Generation

“The world’s largest science project” celebrates Start of Machine Assembly

July 28, 2020 | By Anthony Capkun

July 28, 2020 – Earlier today in southern France, French president Emmanuel Macron and leaders from the European Union, China, India, Japan, South Korea, Russia and the United States declared the official “Start of Machine Assembly” of the world’s largest fusion device.

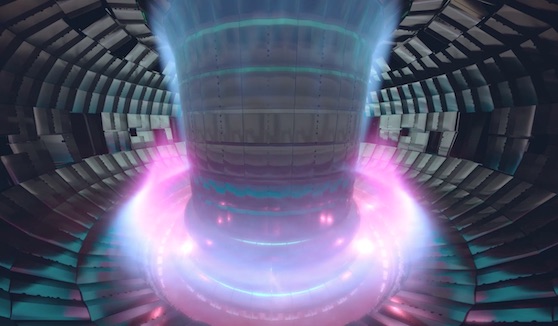

The ITER machine—a.k.a. “the world’s largest science project”—is being created to replicate the fusion power of the sun. Fusion promises clean, reliable energy without carbon emissions; it uses minute amounts of fuel and, according to ITER, presents no physical possibility of a runaway accident with meltdown.

According to ITER, the fuel for fusion is found in seawater and lithium, and is abundant enough to supply humanity for millions of years. A pineapple-sized amount of this fuel is the equivalent of 10,000 tons of coal.

“It is because of the remarkable promise of fusion that the ITER project was born,” says ITER. The 35 partner countries are the European Union (EU, plus the United Kingdom and Switzerland), China, India, Japan, [South] Korea, Russia and the United States.

France is the host country. The EU (along with UK and Switzerland) is the host member, funding 45% of the cost of ITER. Each of the other members funds 9%. About 90% of ITER Member contributions are made in-kind, adding international complexity to an already multifaceted machine, called a tokamak (for “magnetic Torus”).

When finished, the tokamak will be made up of more than 1 million components.

“Constructing the machine piece-by-piece will be like assembling a 3-dimensional puzzle on an intricate timeline,” says Dr. Bernard Bigot, director-general, ITER. “Every aspect of project management, systems engineering, risk management, and logistics of the machine assembly must perform together with the precision of a Swiss watch.”

Assembling the ITER machine will take 4.5 years. At end of this assembly period (December 2025), ITER scientists and engineers will launch FIRST PLASMA—the initial event demonstrating machine functionality.

The plant at ITER will produce about 500 MW of thermal power, and about 200 MW of electric power.

The cost of building and operating a fusion plant is expected to be similar to the cost of a nuclear fission plant, but without the costs and long-term legacy of waste disposal. When ITER is finished, it is expected to demonstrate that fusion power can be generated sustainably on a commercial scale.

DID YOU KNOW?

ITER partners are manufacturing immense, one-of-a kind components for ITER.

The CRYOSTAT is manufactured by India. It is the “thermos” that surrounds the tokamak vacuum vessel and superconducting magnets, which confine the super hot plasma. It is 30-m high and 30-m in diameter. It is the largest stainless steel vacuum chamber ever built. It has four main pieces: the base, lower cylinder, upper cylinder and top lid. The lower cylinder is roughly the same size as Stonehenge. The base weighs 1250 tons, making it the heaviest ITER component.

ITER uses three closely integrated types of magnets to contain, control, shape and pulse the 150 million degree Celsius plasma. To make them SUPERCONDUCTORS, the magnets are cooled internally with -269 degree Celsius liquid helium—the temperature of interstellar space.

TOROIDAL FIELD (TF) COILS are manufactured by Japan and Europe, with components from China, Korea and Russia. More than 40 companies are involved in the manufacture of the 18 TF coils. The coils confine the ionized plasma particles. Each is the height of a 4-storey building and weighs 360 tons.

POLOIDAL FIELD (PF) COILS, manufactured by China, Europe and Russia, are situated outside the TF coil system. The PF coils shape the plasma and hold it away from the walls. There are six PF coils, ranging in diameter from 10 m to 24 m, and weighing up to 400 tons.

The CENTRAL SOLENOID (CS), manufactured by the United States, is the most powerful of ITER’s magnets. The CS is being fabricated in 6 modules. When combined, it will rise 13 m tall (18 m with the support structure) and weigh 1000 tons. The support structures will have to withstand forces equal to twice the thrust of a Space Shuttle lift-off. This component will have the magnetic power to lift an aircraft carrier.

The VACUUM VESSEL, manufactured by Korea and Europe (with the protruding port stubs supplied by Russia) is a hermetically sealed, donut-shaped stainless steel chamber. Inside, the plasma particles spiral around continuously without touching the walls. The volume of plasma contained in the centre of the ITER vacuum vessel is 10x larger than any previous tokamak.

The Building & Assembly Hall have been completed, joined by a 170-m overhead crane rail supporting two 750-ton cranes that will transport and position components.

The cryogenics facility—the largest centralized cryoplant in the world—is 60% complete. It provides the liquid helium for the extremely low temperatures required for superconducting magnets. The equipment comes from China, India, Sweden, Czech Republic, Finland, Italy, Japan, and France. The cryolines are primarily from India.

The magnet conversion buildings supplying power at precisely the right voltage and amperage to ITER’s magnets are using specially designed equipment from China, India, Korea and Russia.

More than 150 specialized tools—some weighing up to 800 tons—will be used to assemble, support, and position the tokamak components.

DID YOU KNOW Canada may have been the host country?

Had things worked out differently, Canada may have hosted the ITER project in Clarington, Ont., which is adjacent to the Darlington nuclear generating station (near Toronto).

Unfortunately, according to Simon Tuck of the Globe & Mail, “Ottawa didn’t kill a Canadian bid to land an important and potentially lucrative international energy project near Toronto: The federal cabinet never got around to making a decision at all”. (December 9, 2003)

Visit ITER here : www.iter.org

CLICK HERE for the YouTube recording of the Live event that occurred earlier in France.

This article—along with other great content—also appears in the October 2020 edition of Electrical Business Magazine.

Print this page